Maintenance department of railway bureau has developed a series of MIS system now. However, because of the lack of general planning, centralized management and efficient coordination, every applied system applies in each own field and the resources can’t be shared; seeing from the system itself, it lacks of unification of system platforms, network structures; applied programs are independent and incompatible, which lead to the blocking of the networks. The data resources can’t be shared and large amounts of hard-wares and soft-wares of computers can not be used efficiently.

This system is the first one to realize the unification at data and port levels in the informatization of maintenance information of railway bureau; which lives up to the planning of maintenance information of railway bureau. It’s the only one to integrate the independent sub-systems developed by national main maintenance informatization companies; it construed an unified applied and maintenance platform of maintenance informatization. It reduces large amounts of constructing and maintenance cost and construction cycle.

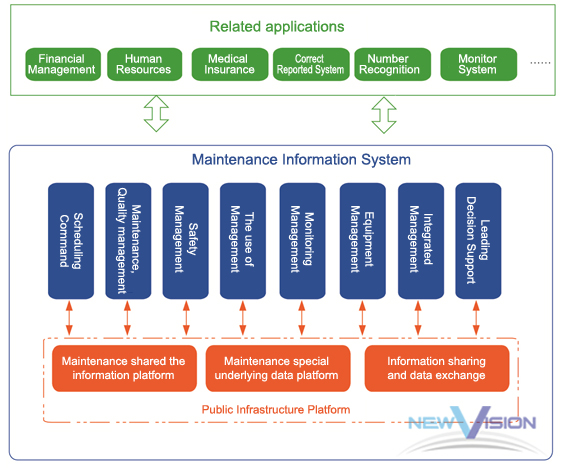

Structure chart of system application

|

(1) Maintenance information system can realize the integrated management of related resources like railway maintenance application and repair operations. It can make the woks more accurate and faster: technological standard statistics of railway maintenance equipment, locomotive operational scheduling, productivity statistics, safety prevention ability analysis, assessment of labor resources utilization condition etc. It can provide solid information basis for leader of all levels to strengthen management force and make scientific decisions.

(2) It construed locomotive operational management comprehensive information platform and it manages, supervises and conducts the locomotive operational plan, trains running diagrams, dormitory and crew.

(3) It construed comprehensive information service platform of repair management and makes real-time monitoring, points warning and on-site conducting for implementation schedule of repair and productivity plan.

(4) It makes the productivity statistics more convenient. Most of the current reports of locomotive operation and repair statistics are written by hand, which is inefficient and the data accuracy can not be guaranteed. After the application of this system, the statistics reports are automatically generated by the system, which not only improve the working efficiency but also guarantee the accuracy and reliable of the data.

|

|

This system has already successfully applied in Shuohuang Railway. It adopts a unified platform, code, port and management, which realized the mutual connection of all systems and removed information isolated. Constructing area of this system includes scheduling center of Shuohuang Railway, transport department, machine vehicle branch; the business it supports involve transport productivity department, monitoring center, transporting management center, repair center, south of Shenchi, back-turning segment of Huangye Port, combined transport management center. All departments are operating in collaboration and it’s tight coordination and distribution of responsibilities.

|